MacAdam steps or SDCM is a common way of expressing color difference in light sources – but is also widely misinterpreted. Here is everything you need to know to use this metric in practice.

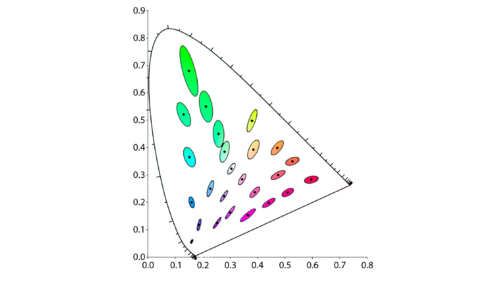

The original MacAdam ellipses were defined by Davis L. MacAdam in his paper “Specification of Small Chromaticity Differences” published in the Journal of the Optical Society of America, Vo. 33, No. 1, January 1943, pp. 18-26. MacAdam wanted to describe just how easy or difficult it is to distinguish one color from another. Within a single ellipse, the probability of the color difference being visible is equal to 39%.

MacAdam wanted to describe just how easy or difficult it is to distinguish one color from another.

SDCM is an acronym which stands for Standard Deviation Color Matching. SDCM has the same meaning as a “MacAdam ellipse”. The original 25 MacAdam ellipse sets are distributed throughout the color space.

Specifically, it is the standard deviation of test colors to the color symbolized by the x,y coordinates of the ellipse center. Assuming a normal distribution of these test color points, a MacAdam ellipse will contain about 39% of the test colors. A 2x MacAdam ellipse will contain about 86% of the test colors, and a 3x MacAdam ellipse will contain about 99% of the test colors.

Not a new thing

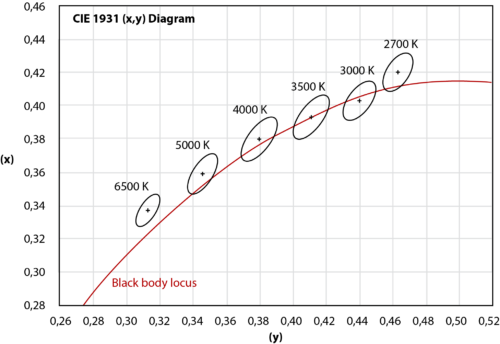

So, MacAdam ellipses existed long before LED. In white, fluorescent tubes, the SDCM values were typically between 3 to 6 depending on the phosphor composition. Typically, SDCM 3 was accepted for indoor use in offices and the like. The varying compositions also called for some standardization – and thus ANSI C78.376-2014 (Specifications for the Chromaticity of Fluorescent Lamps) was published by the IES.

MacAdam ellipses existed long before LED

It is worth noting that most of these ellipses do not actually lie on the black body locus, indicating a slight reddish or greenish tint. As a result of working with the ANSI C78.376 ellipses, a light source that hits the black body locus perfectly at 5000K will have an SDCM value of about 2.4, which may not be very logical.

But back in the day, the ANSI ellipses were a viable way of defining the color variance of fluorescent lamps – where the technology itself defined the ellipse center out what was possible to produce.

Consequently, it makes little sense to judge LEDs by the ANSI C78.376 standard.

Using MacAdam steps to quantify batch homogeneity – color consistency

In LED datasheets, most suppliers use MacAdam ellipses to quantify the color variation of specific LED types being supplied. In this case, there is no point in putting the reference point on the Black Body Locus. LED component suppliers would tend to state the actual production variance, i.e. with the ellipse center placed strategically in the middle of an x,y production outcome test cloud. Some LED suppliers are kind enough to state the coordinates of this center point in their data sheets.

Using MacAdam ellipses to quantify “whiteness”

If the ellipse center point is in fact on the Black Body Locus, the size of the ellipse can be said to be a measure of “whiteness”, or just how purely white a light source can be expected to be perceived.

A common misconception is that MacAdam steps are always a measure of whiteness (in parallel to the Duv metric).

What to do if you are a lamp or a luminaire producer

Regional requirements

Some regional standards and regulations require specific color consistency:

- Energy Star Lamps V2.1 (US): “Reported lamp model light color temperature shall correlate to one of the following nominal CCTs, additionally 9 out of 10 units shall fall within a 7-step MacAdam ellipse or ANSI quadrangle for the designated CCT, per the referenced ANSI document.

- Energy Star Luminaires V2.2 (US): “Passing Test: The lamp tested shall fall within a 7-step MacAdam ellipse for the designated CCT, with ellipses constructed using the Objective Chromaticities detailed in Table 1 of ANSI C78.376-2014 , and the referenced MacAdam publication.”

- EU Regulatory Commission (EU) 2019/2020: “‘Colour consistency’ means the maximum deviation of the initial (…) chromaticity coordinates of a single light source from the chromaticity centre point (cx and cy) declared by the manufacturer or the importer, expressed as the size (in steps) of the MacAdam ellipse formed around the chromaticity centre point (cx and cy). (…).

Color consistency for LED and OLED light sources: Variation of chromaticity coordinates within a six-step MacAdam ellipse or less”.

In order to comply with such regulations, you would need to ensure that your production delivers results that are always within limits – taking into account both the variability of the physical product (LED components and optical components such as reflectors, coatings, lenses, etc.) and the uncertainty of your measurement procedure and instruments.

Measuring a single lamp or luminaire will not tell you if you are in compliance.

You could be lucky or unlucky. In fact, if you need a 95% confidence interval, you need 97 samples (assuming a normal distribution) and 68 samples for a 90% confidence interval. These sample sizes are impossible to work with in a normal light measurement laboratory, so you should take great care to purchase LED components with a high degree of consistency so that you have a reasonable starting point.

To check the consistency of your results, you also need to be in control of where you place the centre of your ellipse, which is your color target.

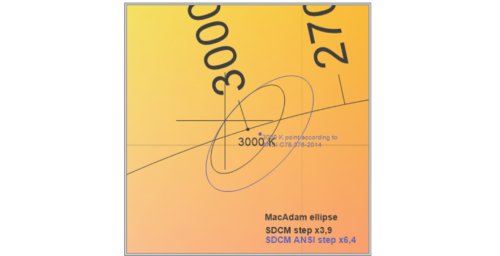

In the USA, with Energy Star regulations, this is not so difficult – at least at first glance. The Energy Star specification requires the use of C78.376-2014. But problems arise when measuring LEDs: What do you do with LEDs that are not 2700/3000/3500/4000/500/6500 K? Following C78.376-2014, there is no meaningful way to express color consistency for, say, a 3200K light source. Also, particularly cold LEDs will fail with a bad SDCM because ANSI C78.376 ellipses are not centred on the black body locus.

In the EU it is equally difficult. It only says that the variation must be within a six-step MacAdam ellipse or less. But it does not say where to place the target, the so-called chromaticity centre (cx and cy).

So there is no way around making your own judgement about where to place the centre of the ellipse, i.e. your target color.

How this works in Viso measurement systems and software

Viso standard SDCM Ellipses

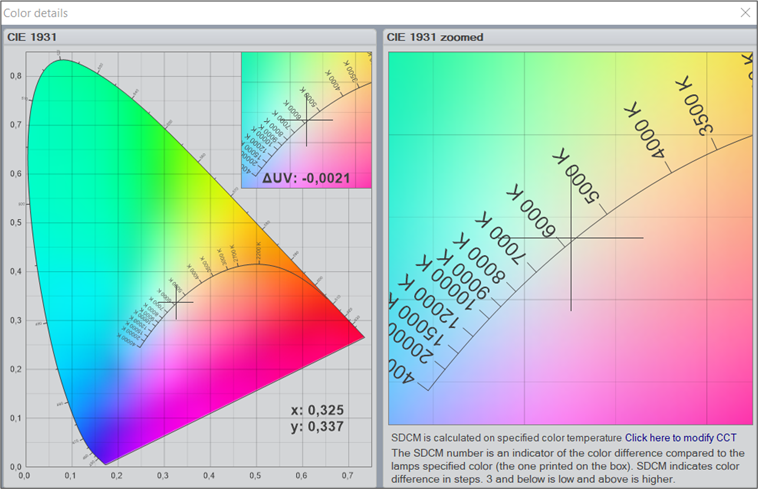

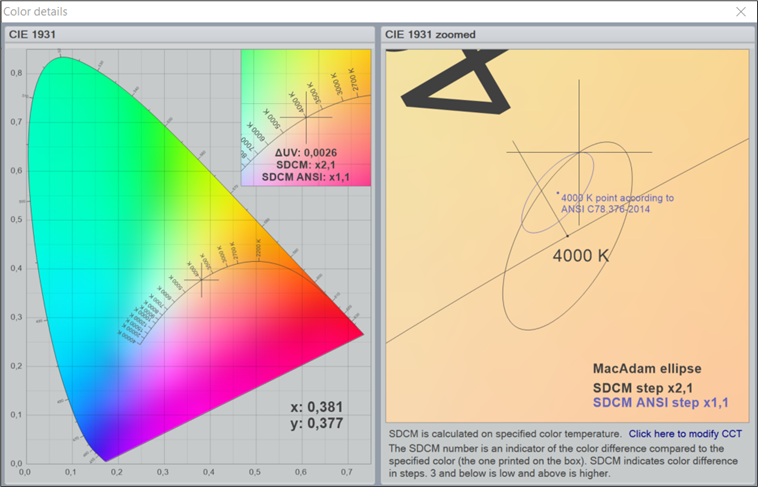

To make it as easy as possible the standard Viso way of specifying SCDM values places the MacAdam ellipse centers on the Black Body Locus (BBL). In this way, the SDCM value can be used to specify how ‘white’ the light source is.

To get the SDCM value, go to Menu -> Edit-> Photometric -> Modify – tick off “modify color temperature” and enter a value, which constitutes an expected color temperature or a target value for the SDCM. This could be the CCT from the LED datasheet.

The SDCM value will now be displayed in the detailed diagram as a matching black MacAdam ellipse and the size of this ellipse indicated below with black text.

The Light Inspector interpolates between the original 25 ellipses to generate ellipses that are indeed centered on the BBL.

This approach is consistent with the coming EU Ecodesign Directive (revision dated 1/10-2019, incl. amendments of May 2021) after which the manufacturer or importer declares the chromaticity center point (“The determined number of (MacAdam) steps shall not exceed the declared number of steps. The center of the MacAdam Ellipse shall be the center declared by the supplier with a tolerance of 0,005 units”).

Please note that the SDCM value is indicated for this device only, and catalogue values of maximum SDCM values may involve measuring many more device. Color consistency may also vary over time.

ANSI C78-376 MacAdam ellipses

Viso Systems has chosen to provide ANSI SCDM values for ellipses as an alternative. The ANSI SDCM value is shown in the detailed diagram as the matching blue MacAdam ellipse and the size of this ellipse is shown in blue text below.

Special MacAdam ellipses

It is also possible to specify a target value (MacAdam Ellipse center) that is NOT on the Black Body Locus. This is necessary for evaluating consistency of for instance colored light sources or white light sources that are deliberately NOT on the BBL:

Go to Menu -> Edit-> Photometric -> Modify. Click the blue text ‘Advanced’ in the top right-hand corner. In the pop-up window, specify the your target color expressed in x,y coordinates.

The CIE 1937 window will change to show that the new ellipse

The small text in red indicates that a custom x,y-target has been set. The black center dot is the special target color.

Contact Viso System to get more information

Write an email to info@visosystems.com to get more information or check out the website www.visosystems.com.