Color differences expressed in MacAdam Ellipses (SDCM)

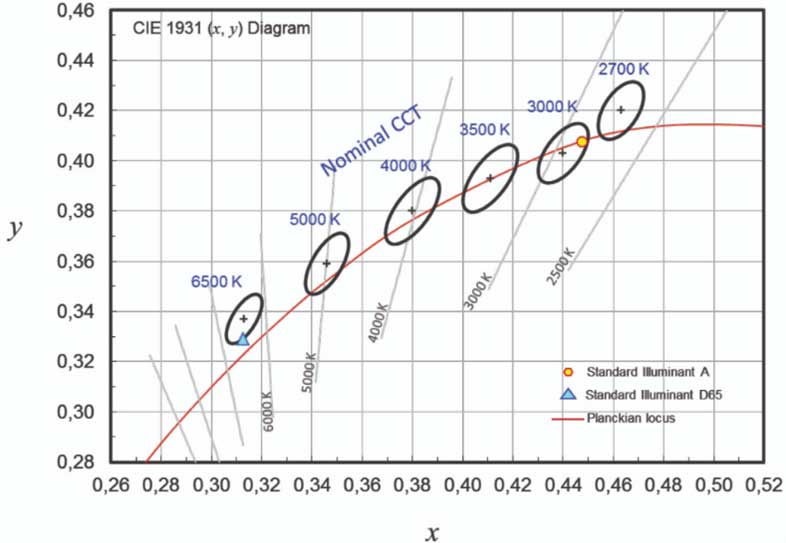

The original MacAdam ellipses were defined by Davis L. MacAdam in his paper “Specification of Small Chromaticity Differences” printed in Journal of the Optical Society of America, Vo. 33, No. 1, January 1943, pp. 18-26. SDCM is an acronym that stands for Standard Deviation Colour Matching. SDCM has the same meaning as a “MacAdam ellipse”. The original 25 MacAdam ellipse sets are spread all over the color space and some are close to the Black Body Locus (BBL).

The ellipses define color differences between two colors – two points in color space. However, in light measurement practice, you often need to specify SDCM deviance for a single measurement. There is no standardized way of establishing a reference point/ellipse center point for this calculation.

How to get your MacAdam ellipses

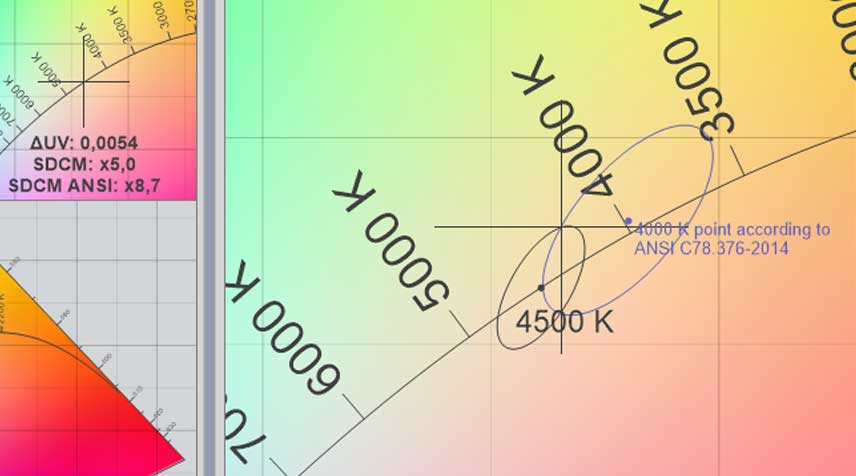

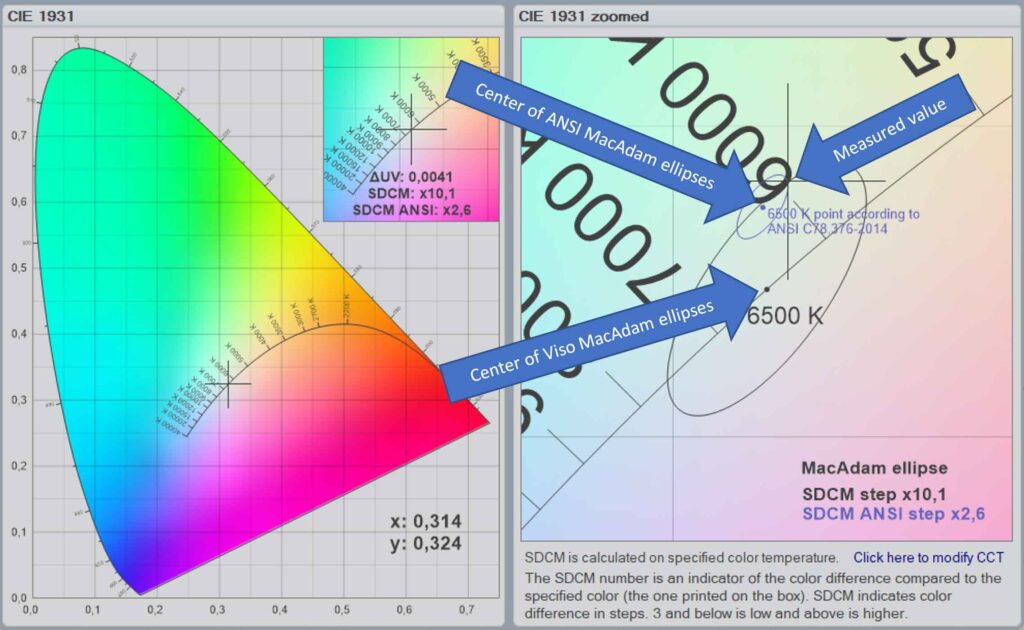

A target value for the color temperature can be entered by clicking the blue text under the diagram (‘Click here to modify CCT’) – or click Menu -> Edit -> Photometric -> Modify – tick off ‘Modify color temperature’ and enter a value (typically as specified by the light source supplier). This will not change the original, measured CCT value, but constitutes a reference point for calculation of the color deviation, i.e., number SDCM steps.

Returning to the ‘Color Details’ window, you will now have mAcAdam ellipses drawn in the right-hand diagram, and SDCM Ellipse size indications in both diagrams.

Viso SDCM Ellipses

There are three main types of SDCM standards in the world:

1. North American Energy Star Standard

Energy Star ANSI C78.376, color tolerance ≤ 7 SDCM

2. EU standard IEC 60081:1997

EU standard ERP, color tolerance ≤ 6 SDCM

3. Chinese GB standard

Chinese standard GB10682-2002, double-end fluorescent lamp performance requirements color tolerance ≤ 5 SDCM.

All of these standards are around 20 years old. They provide help in determining tolerances for discrete CCT values. These CCT values refer to standard flourescent tube CCTs. As they do not take into account that LEDs can have any CCT, Viso Systems has chosen to specify SCDM values for a continuum of ellipses that are all centered on the Black Body Locus (BBL). The SDCM value will now be shown in the detailed diagram as the matching black MacAdam ellipse and the size of that ellipse indicated below with black text. In effect, the Light Inspector software will define a new set of ellipses every time you specify a target CCT. You can choose any CCT as your target.

The Light Inspector defines the specific set of ellipses by interpolating between the original 25 ellipses to generate ellipses that are indeed centered on the BBL. This approach is consistent with the coming EU Ecodesign Directive (revision dated 1/10-2019, incl. amends of May 2021) after which the manufacturer or importer declares the chromaticity center point (“The determined number of (MacAdam) steps shall not exceed the declared number of steps. The center of the MacAdam Ellipse shall be the center declared by the supplier with a tolerance of 0,005 units”).

Please note that the SDCM value is indicated for the measured device only, and the catalog value of a maximum SDCM value may involve measuring more than one device. Color consistency may also change over time.

ANSI C78-376 Ellipses

The American standard ANSI C78.376-2014 specifies reference points and sizes of 6 MacAdam ellipse sets, i.e. for 6 specific color temperatures. These were originally intended for fluorescent light sources and none of them are actually located on the Black Body Locus.

Viso Systems has chosen to specify these ANSI SCDM values for ellipses as an alternative. The ANSI SDCM value will now be shown in the detailed diagram as the matching blue MacAdam ellipse and the size of that ellipse indicated below with blue text.

What is the right way to do it?

In most cases, Viso MacAdam ellipses will provide the lowest SDCM values. But sometimes (as in the example above) the ANSI Ellipses are smaller. As there is no standardized way of doing this you may equally well specify your MacAdam Step value according to the ANSI or the VISO method as long as you can explain the position of your reference point.